Aluminum vs. Steel Light Poles

There are many considerations when upgrading outdoor area lighting and one major one is what type of pole to use. In the beginning stages of selecting a pole, the focus can be put on aesthetic requirements (color, shape and height), load restrictions (fixture, brackets and total EPA) and environmental factors (wind zones/locations and other field conditions).

These environmental factors are key as wind-induced vibration to steel and aluminum light poles can wreak havoc. While light poles are designed to respond to these phenomenons, under the perfect conditions wind vibration can cause structurally-sound poles to fail.

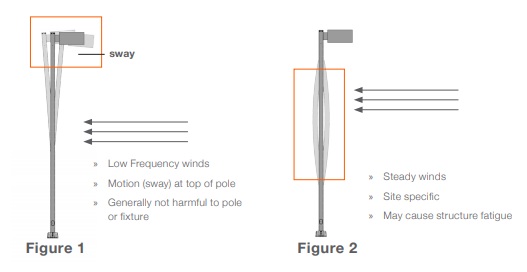

There are two common types of vibration – first-mode vibration and second-mode vibration. First-mode vibration occurs from high-velocity wind gusts, resulting in the top of the pole appearing to sway in the wind. See figured 1 above for the visual representation of this process. Ultimately, first-mode vibration effects tend to be minimal as light poles are designed to move and flex to withstand this level of vibration.

Second-mode vibration, also know as Aeolian Vibration has a tendency to be more destructive for light poles. Aeolian vibration is caused by low-velocity, high-frequency, steady winds in the 5-35mph range. The vibration stems from vortices that form on the back side of the structure as the air passes across the pole. This causes a high-frequency, short-cycle harmonic reaction and stress on the pole is concentrated on the mid-section of the unit. See Figure 2 above for details. While first-mode vibration is easy to see as the fixture at the top sways, second-mode vibration is heard from the audible buzzing noise emanating from the pole. Continued damage through Aeolian vibration can result in cracks, corrosion, or cracked fixtures/lamps.

Given the issues with Aeolian vibration detailed above, many are curious about what causes this perfect storm. There are no documented methods of predicting the occurrence of Aeolian vibration, but certain conditions increase the likelihood of it happening. Geographic location is a prominent factor, as poles in open areas with little to no buildings, trees, etc are particularly susceptible.

Looking at pole types, straight square aluminum poles are most likely to suffer from Aeolian vibration as they have corners and a flat surface. Meanwhile, a round-tapered steel pole is better in this regard as the round shape allows wind to pass around the pole. A combination of materials, ie. aluminum and steel together, has been known to foster more fatigue, so regardless of choice it’s best to just pick one material type.

Kindly provide a similar Case Study on Light Poles structured from Galvanize Steel with 8 Diagonal corners?