Replacing 4′ 4-Lamp T5 54W with 155W LED Highbay 480V

Anytime you have a warehouse environment that you are looking to convert to LED, there is a good chance the existing lighting is either a fluorescent highbay or HID highbay. In this situation shown in the picture above, there are 4′ 4-lamp 54W T5HO fixtures running on 480V.

One thing that is consistent with fluorescent lighting is a stark degradation of light output over time. A band-aid for this system is to continue to replace the lamps as they go out, but unless you do them all at once you will be doing this more often than you’d like. Not to mention the ballasts themselves become a common failure point over time. None of these styles of fixtures are easy to get to as they are commonly 20′ in the air, and performing maintenance on them often means the operation is shut down or at best production is slowed for period of time. This of course means lost money dealing with prolonged maintenance.

Replacing fluorescent T5 lamps with an LED T5 replacement is an option, but gets complicated when you are dealing with 480V. You will need a step-down transformer to get the voltage down from 480V to 277V which an LED T5 tube is more capable of operating on, but that is an added expense per fixture. While they can provide sufficient light levels as replacements, LED T5 lamps lack the feature/light output upside that a new fixture provides.

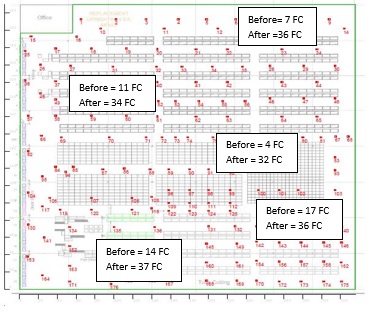

That said, a better solution to consider is a new LED Highbay fixture. There are linear LED Highbays and round LED Highbays; some of it comes down to preference, while the round LED highbays tend to be best for IP68/washdown applications or when replacing a similarly round HID fixture and you are trying to match the footprint. In this dry-rated application in which we are replacing linear fluorescent fixtures, a linear-LED Highbay makes more sense. In turn Premier proposed a 155W linear LED highbay. Check out the huge contrast in footcandle readings as well as the difference in light levels on the After picture below; many of the areas saw light output improvements of 80%. A lot of the low before readings had to do with a fading fluorescent system, however not to be overlooked is what a quality layout can do for optimizing the location of the light fixtures. Another key takeaway from all of this added light is that with it being easier to see in the warehouse, this results in higher production/accuracy and less errors taking place.

The 155W highbay chosen operates at 480V and has a PIR (Passive Infrared) sensor installed for added energy savings when the area is not in use. The settings on the sensor can be set by the factory prior to shipment (usually adds a week or two to lead time) as well as being able to be controlled on the field.

All told, the project is providing the end user with approximately $7,500/year in energy savings. As always, Premier aided the customer in procuring rebates which shaved off a good chunk of the project cost. The life expectancy of the lighting system increased by 3-5 times, which means no lighting maintenance costs for at least 5 years.

Have a similar application you would like to discuss? Maybe you have an early LED system from the mid 2010’s that is due for an improvement? Rebates are now available on LED-to-LED projects as well! Contact Premier Lighting to see how we can help.

No comments yet.